How to Maintain Mechanical & Electrical (M&E) Systems for Industrial Factories Effectively

In the operation of industrial factories, the mechanical and electrical (M&E) system is the “heart” that keeps everything running. If this system encounters a malfunction, the production line may be interrupted, causing significant losses. Therefore, regular M&E maintenance is a key factor in ensuring stable, safe, and cost-efficient factory operation. Let’s explore with TECO how to optimize M&E system maintenance for industrial factories.

The Importance of the M&E System in Factories

The M&E system comprises mechanical and electrical components that help the factory operate smoothly. From lighting, ventilation, and air conditioning to water supply and fire protection – all fall within the scope of M&E.

When properly maintained, the M&E system helps to:

-

Reduce the risk of production interruption.

-

Ensure labor and fire safety.

-

Improve operational efficiency and reduce energy consumption.

-

Extend equipment lifespan and optimize investment costs.

Conversely, neglecting M&E maintenance can expose businesses to electrical short circuits, water leaks, and machinery overloads, resulting in considerable damage. M&E maintenance is not just about “fixing when broken,” but a proactive strategy to prevent risks and sustain long-term production efficiency.

The Role of M&E Maintenance in Factories

The Role of M&E Maintenance in Factories

What Does the M&E System in a Factory Include?

The factory’s M&E system consists of two main groups: Mechanical and Electrical. Each group has its own functions and specific maintenance requirements.

1. Mechanical

HVAC (Heating, Ventilation & Air Conditioning) System:

Controls temperature, humidity, and air circulation. Without regular maintenance, the system may consume more power and reduce cooling performance.

Water Supply and Drainage System:

Ensures a stable, clean water supply without leaks or blockages. Maintenance helps prevent flooding and maintain industrial hygiene.

Compressed Air, Steam, Pump, and Valve Systems:

Provide energy for many production machines. Require regular pressure checks, oiling, and filter replacement.

Fire Protection System (FSS):

Includes fire extinguishers, pipelines, sensors, and pumps. Periodic maintenance ensures the system is ready for emergencies.

What Systems Are Included in M&E?

What Systems Are Included in M&E?

2. Electrical

Lighting, Electrical Panels, and Generators:

Require regular electrical system maintenance to detect early risks such as short circuits, overloads, or damaged cables.

UPS, Automation, and PLC Systems:

Ensure stable power supply and precise equipment control. Industrial electrical maintenance prevents control errors that can cause sudden shutdowns.

Lightning Protection and Grounding Systems:

Protect the entire factory from electromagnetic impacts. Regularly check grounding resistance and lightning conduction capacity.

Each mechanical–electrical group has its own operating characteristics, so the M&E maintenance process must be tailored to each component.

Why Is Regular M&E Maintenance Necessary?

Regular maintenance brings practical benefits to businesses:

-

Prevent Malfunctions:

Detect early signs of damage such as electrical leakage, water leaks, or system overload. -

Maintain Operational Efficiency:

Help machines operate under optimal conditions, saving power and reducing waste. -

Comply with Safety Regulations:

Factories must meet standards for electricity, fire prevention, and the environment. Industrial electrical maintenance helps businesses avoid penalties during inspections. -

Reduce Long-Term Costs:

Maintenance costs are far lower than repair or replacement costs for damaged equipment.

Why is regular M&E maintenance necessary?

Why is regular M&E maintenance necessary?

Effective M&E Maintenance Process for Industrial Factories

A professional maintenance process ensures the M&E system operates stably and synchronously.

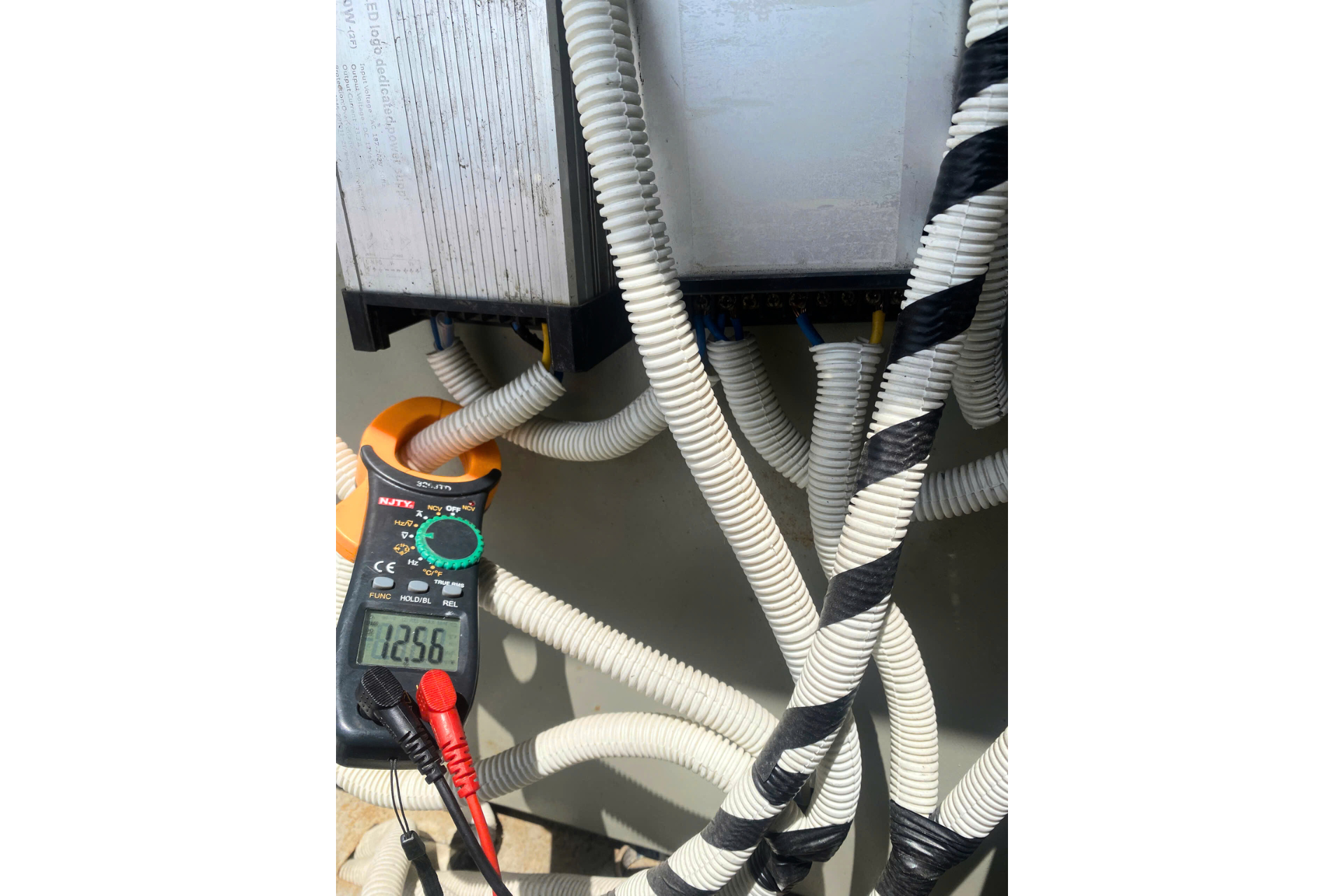

1. Inspection & Current Condition Assessment

-

Inspect all equipment, panels, pipes, valves, fans, and air conditioners.

-

Measure operational parameters: voltage, load current, pressure, temperature.

-

Record any signs of damage or irregularities.

2. Develop a Periodic Maintenance Plan

-

Create monthly, quarterly, and yearly maintenance schedules.

-

Classify systems by importance level.

-

Assign responsible personnel and schedule work to avoid production disruption.

3. Perform Maintenance

-

Clean dust, lubricate, replace filters, tighten bolts.

-

Check wires, switches, breakers, and capacitors.

-

Recalibrate machine parameters and balance the system.

-

Record details of each completed task.

4. Inspection & Acceptance

-

Evaluate post-maintenance efficiency by re-measuring operational data.

-

Ensure the system meets safety and stability standards.

-

Store records and reports for future maintenance tracking.

M&E maintenance process for industrial factory

M&E maintenance process for industrial factory

Notes for Effective M&E Maintenance

1. Choose a Professional Maintenance Contractor

-

Experienced in industrial M&E maintenance.

-

Equipped with engineers and technicians certified in fire safety, electrical, and HVAC systems.

-

Ensures compliance with technical and safety standards.

2. Use Genuine Materials

-

Wires, capacitors, sensors, lubricants, etc., must be of the correct type and origin.

-

Certified materials help systems run stably and reduce failures.

3. Apply Technology in Maintenance Management

-

Use energy monitoring systems and maintenance scheduling software.

-

Provide early warnings for irregularities such as overload, vibration, or overheating.

-

Enhance proactivity in managing the entire system.

4. Train Operating Staff

-

Equip them with basic knowledge of electrical and mechanical risk identification.

-

Guide emergency handling procedures when issues arise.

-

Encourage daily quick inspections to detect abnormalities early.

TECO – A Reputable and Professional Factory Maintenance Contractor in Ho Chi Minh City

TECO – A Reputable and Professional Factory Maintenance Contractor in Ho Chi Minh City

Conclusion

M&E maintenance is an indispensable activity in the management and operation of industrial factories. When performed correctly, it helps businesses achieve stable operations, minimize downtime, save energy and costs, and ensure the safety of people and assets.

With many years of experience in industrial factory maintenance in general and mechanical & electrical (M&E) systems in particular, TECO is a reliable partner to help your factory operate sustainably, safely, and efficiently in the long term.

Contact TECO today for detailed consultation on comprehensive M&E maintenance solutions for your industrial factory.