Process of Positioning Embedded MEP Sleeves in Reinforced Concrete Structures

In construction projects, the MEP (Mechanical, Electrical, Plumbing) system plays a crucial role in ensuring stable and efficient operations. Specifically, the precise positioning of MEP sleeves within reinforced concrete structures must be done accurately from the outset to avoid errors that could impact construction quality and future repair costs. A well-planned positioning process not only optimizes construction progress but also ensures the durability and connectivity of the system. Join TECO in exploring the complete process of positioning MEP sleeves in this article.

Definition

Positioning MEP Sleeves in Concrete Structures refers to the process of identifying and installing MEP (Mechanical, Electrical, Plumbing) sleeves before pouring concrete for floors or foundations. The primary goal is to ensure that the MEP system is installed correctly according to the design, preventing the need for later concrete chiseling and modifications.

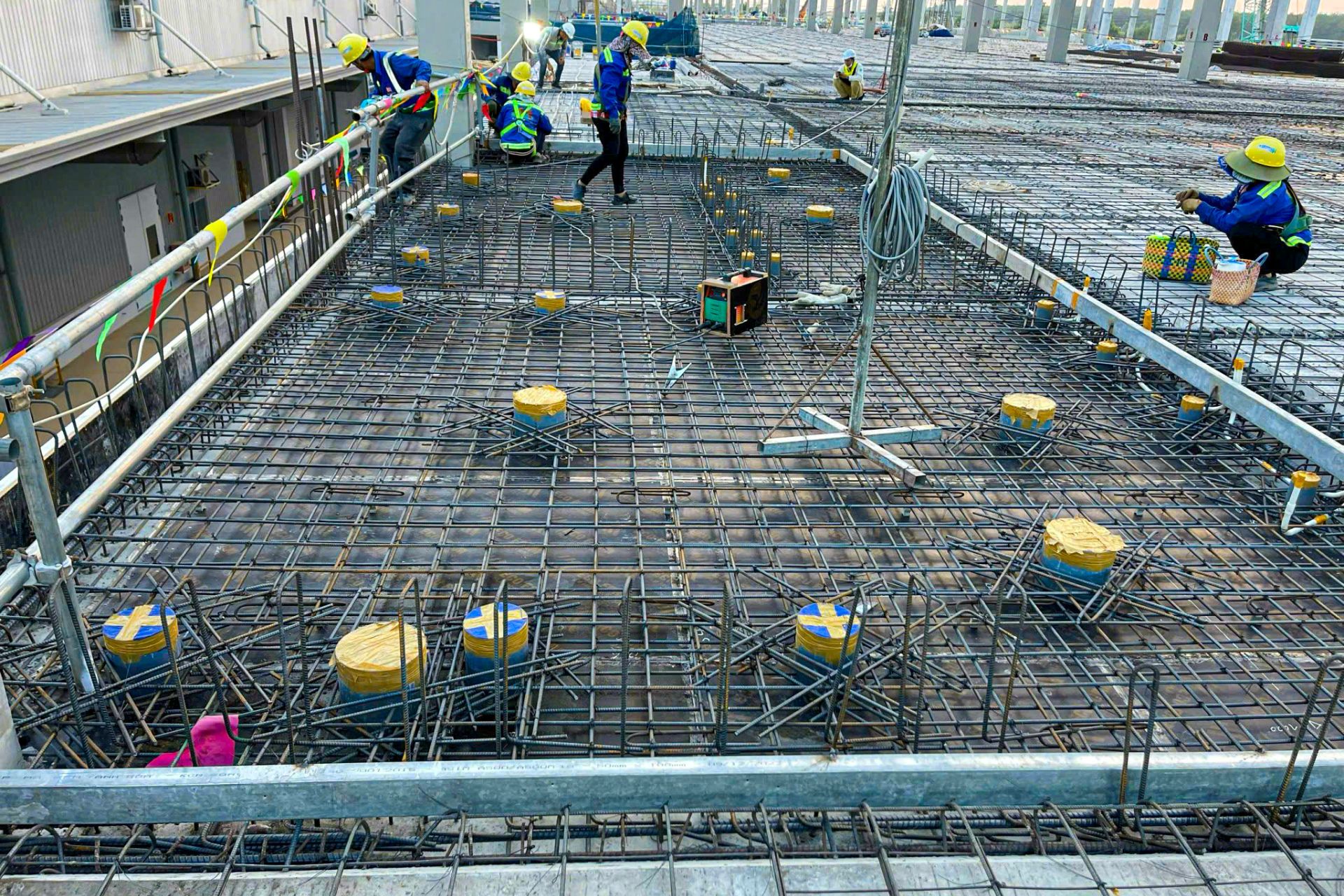

Installing floor reinforcement combined with positioning embedded sleeves through the slab for the MEP system.

Importance of Positioning MEP Sleeves in Reinforced Concrete Structures

The key purposes of positioning MEP sleeves in concrete structures include:

1. Ensuring Accuracy and Structural Integrity

By correctly positioning the sleeves, the MEP pipelines are arranged in accordance with the technical design, preventing the need to chisel into concrete after pouring. This avoids structural damage and reduces the load-bearing capacity of the building.

2. Saving Costs and Construction Time

Proper placement of MEP sleeves minimizes the need for drilling and chiseling, reducing repair and material costs. Additionally, it accelerates construction progress, allowing MEP installation teams to proceed smoothly without interruptions.

3. Enhancing Aesthetics and Utility

Proper MEP sleeve positioning ensures that plumbing, electrical, HVAC, and fire protection systems are neatly arranged, preventing the exposure of technical pipelines that may affect aesthetics.

4. Facilitating Maintenance and Future Upgrades

When MEP sleeves are correctly positioned, future maintenance, repairs, or replacements become more manageable. This minimizes the risk of structural damage when modifications to the MEP system are needed.

The significance of MEP sleeve positioning work.

Process of Positioning MEP Sleeves

Step 1: Understanding the MEP Drawings

Before positioning the MEP sleeves and pouring concrete, a shop drawing (detailed construction drawing) is required. The technical team must thoroughly review the MEP, structural, and architectural designs to ensure that the sleeve locations do not interfere with the structural integrity of the project. The construction team must determine the size, location, number of sleeves, and appropriate installation method.

Step 2: Identifying Installation Locations

Based on the construction drawings, the technical team pinpoints the exact locations for MEP sleeves on the floor plan. This step must be executed with precision to prevent conflicts between the MEP system and the building structure. Installation points must not interfere with load-bearing steel reinforcements and must comply with project technical requirements.

Step 3: Fabricating and Preparing Sleeves

Once locations are determined, the construction team fabricates the sleeves according to the required size and material. MEP sleeves are typically made from PVC, steel, or heat-resistant pipes. The pipes must be cut accurately, and their ends must be properly cleaned to ensure no obstructions during installation.

Step 4: Fixing Sleeves to the Formwork

Before pouring concrete, the MEP sleeves are securely fastened to the formwork or reinforcement system. This prevents displacement or deformation during the concrete pouring process. Common securing methods include:

- Using steel wire to tie the sleeves to the reinforcement framework.

- Attaching directly to the formwork with specialized adhesive or brackets.

- Using supports or holders to keep the sleeves in place.

Construction of the underground drainage and technical pipe system.

Step 5: Inspection and Adjustments

Prior to concrete pouring, the supervision team must check the positioning, elevation, and stability of the MEP sleeves. Any discrepancies from the design must be promptly corrected. The key inspection parameters include:

- Diameter and location of the sleeves.

- Depth of embedding within the concrete.

- Alignment of the sleeves for seamless future MEP installation.

Step 6: Pouring Concrete

After completing the inspection, concrete is poured following the construction process. During pouring, close monitoring is required to prevent sleeve displacement or deformation. If any misalignment occurs, immediate corrective measures should be taken, such as repositioning or reinforcing the sleeve location.

Installing sleeves through beams – image of the sleeves after the concrete has been completed.

Installing sleeves through beams – image of the sleeves after the concrete has been completed.

Key Considerations When Positioning MEP Sleeves in Reinforced Concrete Structures

- Logical Pipeline Arrangement to Prevent Conflicts

Ensure that pipelines are arranged to avoid intersections or conflicts between plumbing, drainage, electrical, and ventilation systems. Poor planning can lead to costly modifications later. - Securing Sleeves Before Concrete Pouring

MEP sleeves must be firmly fixed with supports or wire ties to prevent movement during concrete pouring. This maintains the correct position and elevation as per the design, reducing the risk of cracks or breakage due to concrete pressure. - Sealing Sleeve Openings to Prevent Concrete Entry

Before pouring, all sleeve openings must be sealed to prevent concrete from entering and causing blockages that could complicate subsequent installations. - Pre- and Post-Pour Inspections

A thorough inspection of the MEP sleeve system should be conducted before and after concrete pouring to identify any errors. If minor deviations are found, adjustments should be made immediately to avoid future chiseling and reconstruction.

Conclusion

Positioning MEP sleeves in reinforced concrete structures is a critical process that requires high precision and close coordination among construction teams. Following the correct procedure from the start helps minimize errors, save costs, and ensure the efficient operation of the building. Engineers and construction teams must strictly adhere to these steps to achieve the highest quality for their projects.

TECO hopes this article has provided valuable insights into the significance and process of positioning MEP sleeves in reinforced concrete structures.