What is Reinforced Concrete? Advantages and Disadvantages of This Material

Reinforced concrete is an essential building material widely used in civil construction, industrial factories, bridges, roads, and urban infrastructure. Not only is it durable over time, but it also offers many outstanding advantages, ensuring the quality and safety of construction projects. Let’s explore this popular material in detail with TECO through the article below.

Definition of Reinforced Concrete

Reinforced concrete is a construction material that combines concrete and steel. These two materials have different mechanical properties and work together to bear loads. Concrete has excellent compressive strength, while steel has superior tensile strength. This combination takes advantage of both materials, allowing structures to withstand both compression and tension, making it suitable for various types of construction.

What is reinforced concrete?

Main Components of Reinforced Concrete

As per the definition, reinforced concrete is formed by combining concrete and reinforcement steel to leverage their respective strengths. Its basic structure consists of two main components:

1. Concrete

Concrete is an artificial material made from a mixture of cement, sand, gravel (or stone), and water. When hardened, concrete has high compressive strength but weak tensile strength.

Composition of Concrete:

- Cement: Acts as the binding agent.

- Sand: Fills the gaps in the mixture with fine particles.

- Gravel (or stone): Larger aggregates that primarily bear the load.

- Water: Hydrates the cement, facilitating hardening and bonding.

- Additives (if any): Used to enhance concrete properties, such as waterproofing agents, water reducers, and plasticizers.

Basic components of reinforced concrete

2. Reinforcement Steel (Rebar)

Reinforcement steel provides tensile strength, compensating for concrete’s weakness in handling tension.

Common Types of Reinforcement Steel:

- Plain Steel Bars: Smooth round bars, rarely used in major load-bearing structures.

- Deformed Steel Bars: Ribbed or textured bars that improve adhesion with concrete, commonly used in beams, columns, and slabs.

- Welded Wire Mesh: Pre-welded steel grids, often used for floor slabs or thin concrete panels.

Key Characteristics of Reinforced Concrete

- High compressive strength: Concrete is highly resistant to compression but weak in tension, requiring reinforcement with steel.

- Strong adhesion between concrete and steel: This ensures the materials function as a unified structure under load.

- Bonding force: As concrete hardens, it forms a strong bond with steel, allowing effective force transfer and optimizing strength.

- Heavy material density: Ranges from 2,200 – 2,500 kg/m³, much heavier than wood and composite materials.

- Low thermal and acoustic conductivity: Helps reduce noise and stabilize indoor temperatures.

- Similar thermal expansion coefficients: Concrete and steel expand and contract at similar rates under normal temperature fluctuations (below 100°C), maintaining their bond.

Some highlight characteristics of reinforced concrete.

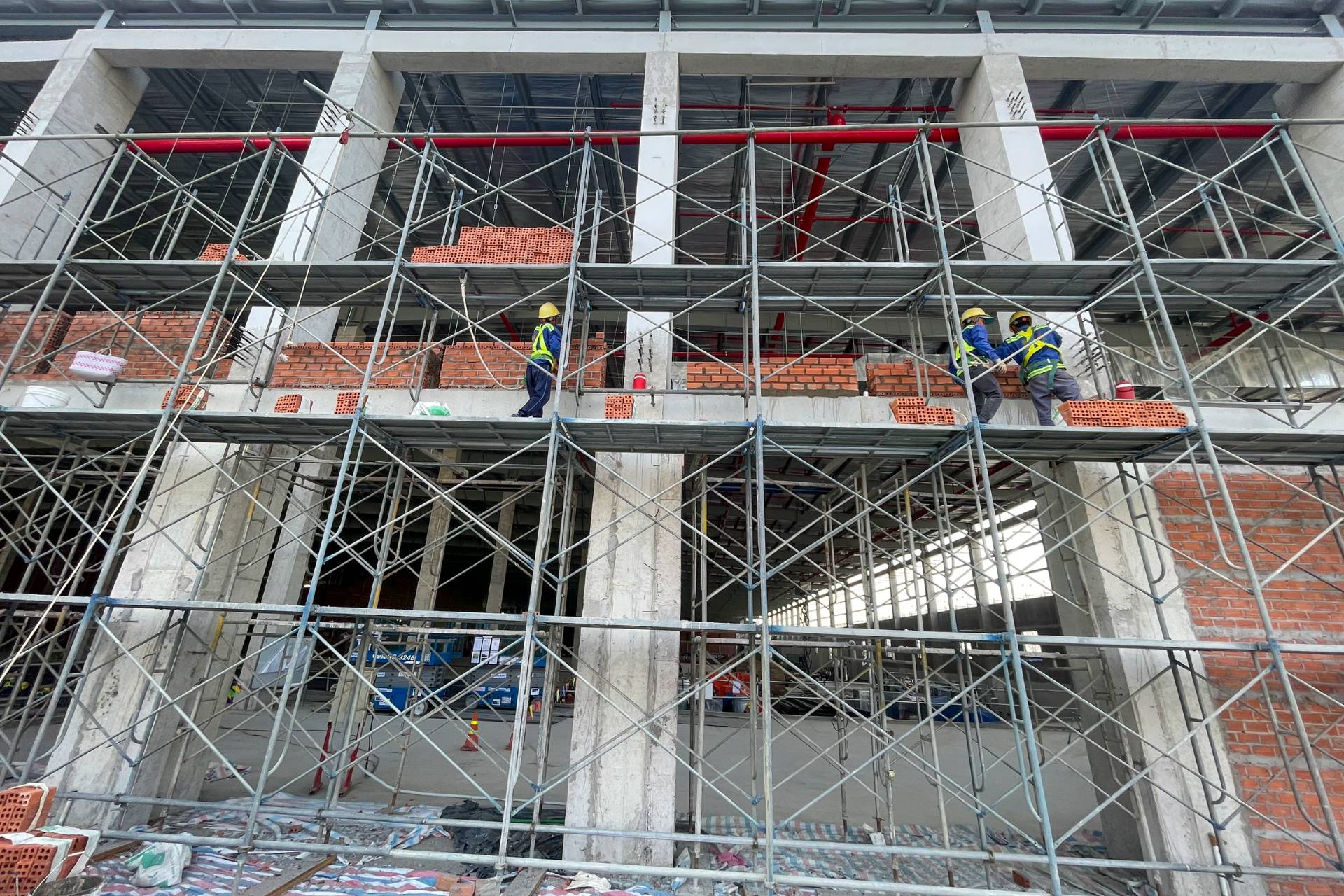

Applications of Reinforced Concrete in Industrial Construction

Reinforced concrete is a primary material in industrial factory construction due to its high load-bearing capacity, durability, and cost-effectiveness. It is widely used in key structural components such as:

- Foundation: Transfers the load to the ground, ensuring stability and resistance to settlement.

- Columns: Bear vertical loads and support the upper structure, resisting lateral forces.

- Beams: Connect columns and bear loads from floors and roofs, distributing force evenly to the foundation.

- Floors: Provide strong, durable surfaces for production activities.

- Walls: Serve as enclosures and may also contribute to structural strength.

Thanks to these characteristics, reinforced concrete is indispensable in industrial construction, ensuring durability, safety, and long-term efficiency.

Advantages and Disadvantages of Reinforced Concrete

Advantages

1. High Strength and Durability

- Excellent compressive strength: Suitable for heavy-load structures.

- Enhanced tensile and flexural strength: Steel reinforcement significantly improves tensile resistance.

- Shear resistance: When designed with proper reinforcement, it effectively resists shear forces.

2. Long Lifespan and Corrosion Resistance

- Anti-corrosion: Concrete protects embedded steel from rusting.

- Fire resistance: Concrete withstands high temperatures and does not burn, providing fire protection for structures.

3. Versatile Formability

- Moldability: Can be shaped into various structures, from simple to complex, using formwork.

- Ease of construction: Can be cast in place or prefabricated into different structural elements for easy installation.

4. Fire-Resistant Properties

- Superior fire resistance

- Non-combustible material: Provides excellent thermal insulation.

- Structural integrity during fires: Concrete protects reinforcement steel, maintaining stability and allowing safe evacuation while reducing damage.

Disadvantages

Despite its outstanding advantages in industrial construction, reinforced concrete also has some notable drawbacks that affect construction efficiency and costs.

Disadvantages of reinforced concrete

1. Heavy Weight and Structural Impact

- With a density of 2,200 – 2,500 kg/m³, reinforced concrete structures are significantly heavier than lightweight materials like prefabricated steel.

- Increased structural weight necessitates larger foundations, leading to higher construction costs.

2. Long Construction Time

- The construction process involves multiple steps: formwork installation, steel reinforcement placement, concrete pouring, and curing.

- Concrete requires 7–28 days to achieve full strength, extending project timelines compared to faster modular steel construction.

3. Shrinkage and Cracking

- Concrete naturally shrinks as it hardens, which can lead to surface or structural cracks if not managed properly.

- Cracks may compromise water resistance, accelerate reinforcement corrosion, and reduce overall durability.

4. Environmental and Transportation Impact

- Cement production releases significant CO₂ emissions, contributing to environmental pollution.

- Transporting heavy concrete and steel materials increases logistics costs and greenhouse gas emissions.

Conclusion

Reinforced concrete remains one of the most important and widely used construction materials today. TECO hopes this article has provided a comprehensive understanding of its key characteristics and benefits. This material not only ensures the quality and longevity of structures but also plays a crucial role in the advancement of modern construction.